Mercedes-Benz Ponton

Diesel Engine Overview

History / Operation / Advantages / Disadvantages

View the Ponton Diesel Technical Data page

Photo 1. 1959 Mercedes-Benz Type 190D

History / Operation / Advantages / Disadvantages

View the Ponton Diesel Technical Data page

Photo 1. 1959 Mercedes-Benz Type 190D

Termed a compression-ignition engine, the diesel depends upon the heat generated by compression in the cylinders to fire the fuel, which in this case is diesel oil. Abbreviated "OM" by Daimler-Benz, diesels are also known as oel motors (oil motors).

History

Credit for inventing the diesel engine concept goes to the German engineer Doctor Rudolf Diesel. He first presented his concept for a "rational heat engine" in 1892. That was 20 years after the first gasoline engine was built in 1863 by a Frenchman named Lenior. Doctor Diesel originally tried to build an engine using coal dust as a fuel. It was readily available and cheap. Unfortunately, the idea did not work. It was not until 1897 that Doctor Diesel, aided by another scientist named Lauster and the engineers of the M.A.N. Company, produced a working liquid fuel engine.

Photo 2. 1936 Mercedes-Benz Type 260D — the first series production diesel passenger car

The first diesel powered truck was produced in 1923 by Daimler-Benz. Also, the first series production diesel automobile was introduced at the 1936 Berlin Auto Show by Daimler-Benz. The Mercedes-Benz Type 260D was intended to be used primarily as a taxi. It was a 4 door sedan, which had a 2.6 liter, 4 cylinder engine giving a top speed of about 60 mph. About 2,000 were built before World War II began.

Diesel Engine Operation

Like gasoline engines, diesels must mix air and fuel into a combustible mixture. Individual molecules of fuel must enter into close proximity with molecules of oxygen for combustion to take place. However, the ways of achieving this mixture and igniting it are different. First of all, the air drawn into the combustion chamber of a diesel does not contain any fuel. Nor does a diesel generally have an air valve or throttle. The engine takes in as much air as the restrictions in the air flow passages and the speed and displacement of the engine will allow. Diesels draw in as much as 600% more air than is needed for combustion at idle speeds and as much as 25% extra air at full throttle. Diesels mix fuel and air directly in the combustion chamber. The speed of the engine is governed by the amount of fuel introduced. Without some sort of governor, the engine would run away, producing as many as 2,000 power impulses per second. High pressure injectors are used to spray the diesel fuel into the combustion chamber. Unlike gasoline engines, the injection and subsequent air/fuel mixing occur late in the compression stroke. And unlike gasoline engines, diesels operate at much higher compression ratios, in the range of 14:1 to 24:1. This means the air pressure in the combustion chamber is 35 to 45 times greater than normal atmospheric pressure (14.5 pounds per square inch). To obtain good penetration of fuel into the pressurized air and to achieve good atomization and fuel distribution, the velocity of the air droplets has to be proportionally higher. Diesel fuel injection systems therefore always operate at high pressures, in the range of 250-350 atmospheres. Adding the pressure created by the combustion process with the pressure due to the compression stroke results in peak combustion chamber pressures of 55 to 75 atmospheres. Diesels operate at such high pressures in the combustion chamber because of the way the fuel is ignited. As air is compressed, it becomes hotter. By the time fuel is injected into the combustion chamber of a diesel engine, the air is so hot that the fuel self-ignites without the need for a spark plug (although glow plugs and other means are sometimes used to help start cold engines). This is why diesels are often called self-ignited engines.

The increased compression ratio also has another effect. Higher compression ratios result in greater thermal efficiency. Thermal efficiency is a measure of how well an engine converts chemical energy into mechanical force. In other words, if the thermal efficiency of an engine is 40%, then 40% of the fuel it uses is converted into work and the other 60% is wasted as heat loss from the exhaust pipe or radiated into the atmosphere via the radiator. However, even though higher compression ratios provide self-ignition and better thermal efficiency, the increased pressures and stresses require diesels to be stronger and stiffer than comparable gasoline engines.

There are also other differences: many gasoline engines have carburetors to mix air and fuel; diesels do not need them. Gasoline engines require elaborate ignition systems including spark plugs, coils, distributors, etc. Diesel engines are self-igniting and do not require any of these components.

Advantages of Diesel Engines

Economy

One of the main advantages of diesel engines is fuel economy. A diesel engine generally uses less fuel than the same size gasoline engine in comparable vehicles. One reason for a diesel's fuel economy is the thermal efficiency of the diesel fuel compared to gasoline.

Low Emissions

Diesel engines produce lower levels of certain kinds of pollutants than gasoline engines. Because the peak combustion temperatures of diesel engines are lower than gasoline engines, NO (nitric oxide) formation is less. However, diesel engines do produce more particulate or solid pollutants than gasoline engines. This is the smoke commonly seen coming from diesel exhaust pipes. Until recently (c. 1980), particulate emission, although not particularly attractive, was not considered a significant health hazard. Those ideas have been challenged and has forced diesel engine manufacturers to reduce the solid emissions produced by their engines.

Reliability

It is true that most truck and industrial diesel engines remain in service longer than most passenger car gasoline engines. It is also true that Daimler-Benz has a reputation for building durable engines. And it is true that a diesel engine has to be stronger than a gasoline engine to withstand the increased combustion chamber pressures and temperatures. However, it does not follow that a diesel engine must last longer than a gasoline engine. It depends on the manufacturer's goals. When selling to industrial and commercial markets, it is important to have a long lasting product. So, the manufacturers of commercial diesels overbuilt their engines in comparison to gasoline engines. The passenger car engines built by Daimler-Benz were also overbuilt because the same engines that went into private use were also sold for commercial applications (like taxi and fleet use) where extreme durability is required.

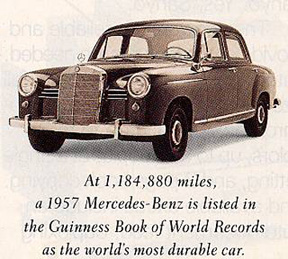

Photo 3. Robert O'Reilly (circa 1980) in his 1957 Type 180D with 1,184,880 miles

In 1978, when the Mercedes-Benz Type 300SD (W116) was introduced, the firm launched the "Great Diesel Search" to find out how long lasting and rugged their diesel passenger cars really were. The oldest one was found to be a 1938 Type 260D owned by Paul Dauer of Chicago, but with only 84,742 miles behind it. The high mileage car turned out to be owned by Robert O'Reilly of Olympia, Washington, whose 1957 Type 180D (W120) had traveled 1,184,880 miles.

Photo 4. Guiness Book of World Records

The high mileage Type 180D was then featured in an advertising campaign during the 1980s, which emphasized the durability and long lasting value of Mercedes-Benz passenger cars. Mr. O'Reilly's car was also listed in the Guinness Book of World Records as "the world's most durable car." The 2nd place award in the "Great Diesel Search" went to Edward Donaldson of Eugene, Oregon who put 912,493 miles on his 1968 Type 220D/8 (W115). Mercedes-Benz of North America, Inc. awarded a new 300SD to the owners of the oldest and highest mileage cars. The top 5 cars in the mileage class had traveled a total of 4.6 million miles.

Disadvantages of Diesel Engines

Lower output and torque

Given identical displacement engines, a diesel will only produce 65% of the horsepower and 80% of the torque of a gasoline engine.

Higher first cost

Because diesel engines need to be larger to give the same horsepower and torque as a gasoline engine and because they need to be stiffer and stronger to withstand the additional pressures and temperatures, diesel engines usually cost more to make. However, in high mileage applications (taxi, truck) the extra cost is usually offset by better fuel economy and reduced maintenance.

Increased noise

Owing to the operating characteristics of diesels, they are usually noisier than gasoline engines, particularly just after cold starts. This noise, which is actually a kind of detonation or spark knock, is not considered harmful.

Smoke

Diesels produce more particulate or visible emission than gasoline engines.

References

- Diesel Engines for Automobiles and Small Trucks / Author: Tom Weathers / ISBN: 0-8359-1288-4 / © 1981 by Reston Publishing Company, Inc.

- The Mercedes-Benz Story / Author: Louis William Steinwedel / © 1979 by Rand McNally / Library of Congress Catalog Card Number 79-83727