Colin Wilson / Australia / colinw@hotkey.net.au

Dear Editor,

A message from "Down-Under." The attached article and photos were prepared for publication in Around the Benz - the magazine of the Mercedes-Benz Club of Victoria, Australia. I have forwarded the material for your consideration as a suitable technical contribution to the Mercedes-Benz Ponton website.

Best Regards,

Colin Wilson

August 15, 2010

Procedure

The Hydrak System, made by Fitchel and Sachs, was introduced in August 1957 as an optional extra at a cost of DM 450. It was one of the first attempts to develop an automatic transmission.

Despite early popularity it was not readily accepted on resale as some owners held onto the lever while driving, which resulted in a burnt-out clutch.

After more than 50 years, it has gained greater appreciation by owners who understand the system; as it performs very well when it is correctly set up and maintained.

Successful operation requires the system to maintain vacuum for at least five hours. A small leak in the vacuum tank, cracked hose, faulty vacuum valves or unions can mean a loss of vacuum with a subsequent drop in performance that may not be correctly diagnosed.

Most of the system can be repaired and adjusted with two exceptions. The seals between the fluid coupling and drive shaft, and the diaphragm in the servo that activates the clutch, are no longer available as original spares.

A Hydak servo usually requires repair because the diaphragm fails. If a replacement diaphragm were available, it would not be easily refitted because of the difficulty in separating and rejoining the two halves of the unit.

Fortunately there is a diaphragm, which with some modification, can be successfully fitted into the servo unit.

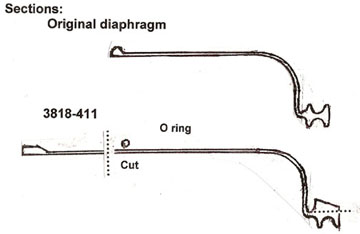

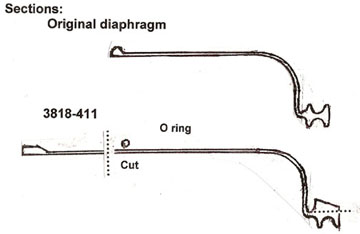

A Protex servo diaphragm 3818-411 (originally Lockheed) is the right diameter and can be fitted to the servo by cutting out the thick rim in the center so that it can be clamped within the central section of the servo that attaches to the pull rod, and grinding/trimming one side of the outer edge to match the metal halves of the servo unit. (Refer diagram 1)

Diagram showing how alternative diaphragm is cut/modified to fit servo

The original diaphragm has a thicker inner edge that is held in place in a groove between the plates that are fixed to the clutch pull rod. When fitting the new diaphragm place a circle of 4.2mm O-ring in the groove to hold the new diaphragm in place.

Once this has been achieved the two halves can be held together with a clamp from a Westinghouse 30/30 brake servo or similar servo as used for truck brakes. These clamps are quite solid to withstand the pressures relevant to truck brake systems and should be available from a trucking company waste bin. When you find the correct one, it will fit straight on and hold more firmly than the original fixed clamp.

Any future need to replace a diaphragm will be easy and relatively inexpensive.

I carried out the above repair and it has been very successful.

Diaphragm 3818-411 (Originally Lockheed)

Servo and clamp

Servo with clamp fitted

Section of servo showing clamp holding halves together

Three shots showing position of grinder used to cut edge of diaphragm (Great care and patience is required - or start again - very difficult to cut with a blade)

New diaphragm (center cut out) with holding plates and O-ring

Parts Suppliers

Search the web for...

"Bremskraftverstärker Membrane Manschette Lockheed Alfa"

or...

"Brake booster diaphragm seal Lockheed Alfa 3818-411"

As of August 2010, the diaphragm costs about €30.

Created: August 15, 2010 / Jeff Miller

© www.mbzponton.org